CCTS CHINA Cold Chain RFID Asset Management System, Making Cold Chain Management Worry - Free with 'Codes'

Release time:2025-02-28

In the current context of the rapid development of the cold chain logistics industry, cold chain pharmaceutical logistics and cold chain pharmaceutical packaging are facing numerous challenges. From the transportation and storage of vaccines and drugs to the temperature - control guarantee of pharmaceutical packaging materials, any problem in a single link may endanger product quality and safety. The CCTS CHINA Cold Chain RFID Asset Management System is precisely the "golden key" to solving these problems.

Directly Addressing Pain Points and Breaking the Deadlock Precisely

In the actual scenarios of cold chain management, there are a wide variety of cold chain assets such as boxes and ice packs, making management and statistics extremely difficult. Chaos and loss are common occurrences. Take a large - scale pharmaceutical logistics warehouse as an example. Every day, hundreds or even thousands of insulation boxes and ice packs of different specifications need to be handled. Manual management is highly prone to situations where assets cannot be found or recording errors occur. It is difficult to count the usage frequency and duration of ice packs, and it is challenging to control their life cycle and quality. Manual recording of the energy storage and defrosting time of ice packs is not only inefficient but also error - prone, resulting in insufficient energy storage of ice packs and over - time cold release, which seriously affects the safety of pharmaceutical cold chain transportation. Once the temperature in the refrigerated box exceeds the standard, due to the lack of identity markings and usage records of ice packs, it is impossible to trace the source of the problem.

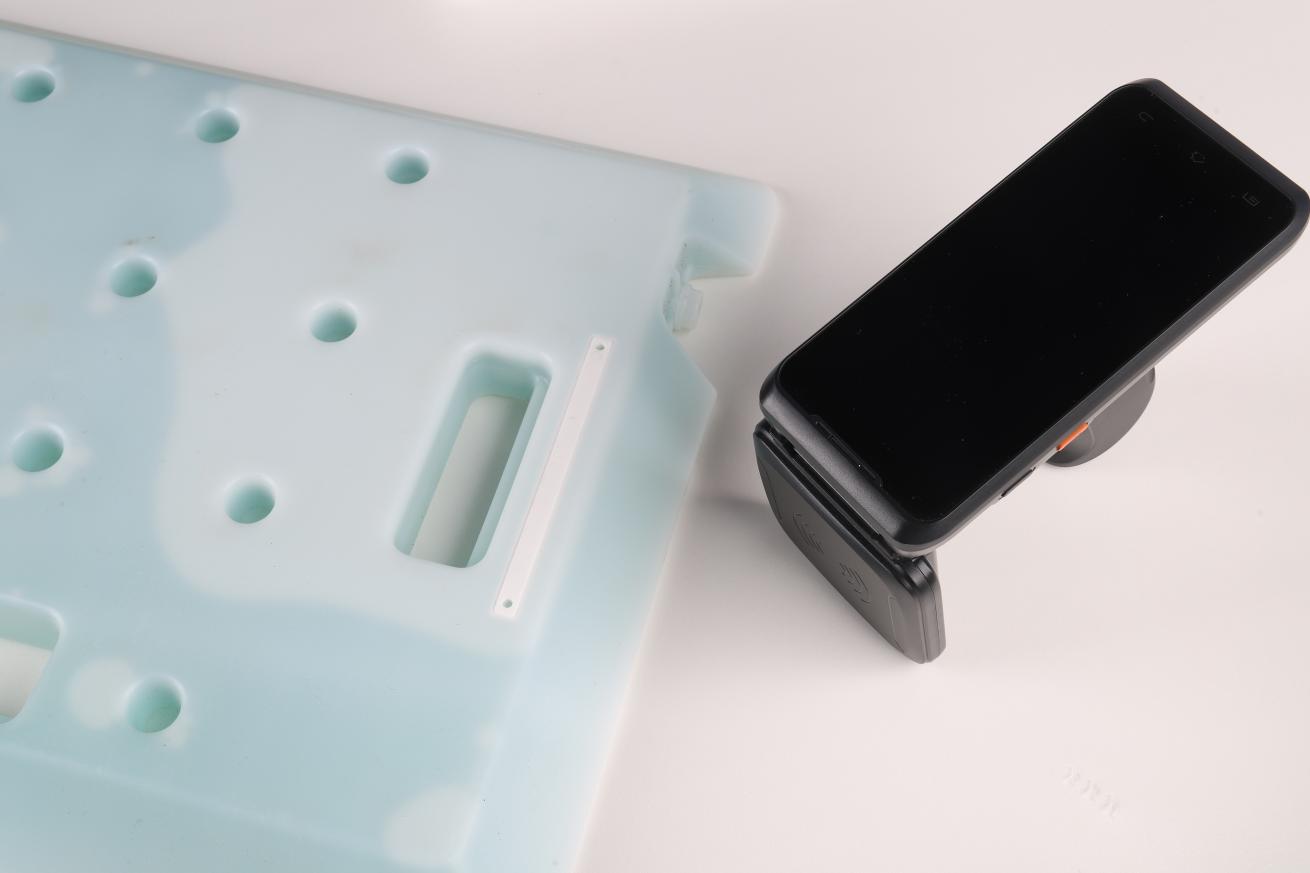

The CCTS CHINA Cold Chain RFID Asset Management System directly targets these pain points. By completely associating cold chain products with individual ice boxes, boxes, and recorders, it generates an electronic cold chain tracking form and assigns an "electronic ID card" to each asset. The serial numbers of ice boxes, boxes, and recorders are bound to the unique RFID identifiers. Combined with handheld radio - frequency terminals, customized APPs, and an intelligent cold chain management system, the combination of software and hardware makes management more efficient and operation simpler.

Intelligent Sensing and Data Flow

The CCTS CHINA Cold Chain RFID Asset Management System takes RFID technology as the core and utilizes the Internet of Things to achieve real - time data transmission and interaction. After affixing RFID electronic tags to cold chain assets, these tags are like intelligent sensors, continuously collecting asset status information, including key data such as location and temperature. The RFID readers deployed in scenarios such as warehouses and transportation vehicles will periodically scan the surrounding electronic tags. Once a signal is identified, they will quickly read the information in the tags and transmit the data to the server of the intelligent cold chain management system through wired or wireless networks. The server analyzes, stores, and processes the received data, and then presents the key information to management personnel through customized APPs and other terminal devices, achieving all - round and real - time monitoring of cold chain assets.

Significant Advantages and Breaking through Limitations

• Efficient and Precise Asset Management: Traditional manual asset inventory is time - consuming, labor - intensive, and error - prone. The CCTS CHINA system uses RFID technology to quickly inventory massive cold chain assets, instantly identify and count the quantity, location, and status of assets, greatly improving asset management efficiency and reducing labor costs.

• Real - Time Dynamic Temperature Monitoring: The system integrates high - precision temperature sensors, which can collect the temperature of the cold chain environment in real - time and accurately record every temperature fluctuation. Different from the discrete data recording of traditional temperature and humidity recorders, the CCTS CHINA system realizes continuous monitoring of temperature data. Once the temperature is abnormal, it can issue an alarm immediately to ensure the quality and safety of cold chain products.

• Deep Data Mining and Analysis: With the help of big data algorithms, the system deeply mines the massive data collected, analyzes the usage frequency of assets, the temperature change patterns during cold chain transportation, etc., providing a strong basis for enterprises to optimize their operation strategies. For example, by analyzing historical data, the procurement quantity and usage cycle of ice packs can be reasonably planned to reduce operating costs.

• Seamless Full - Process Traceability: From asset warehousing to final recovery, the Saixin system records the detailed information of each link, forming a complete traceability chain. When problems occur, the specific link and responsible person can be quickly located, providing clear clues for problem - solving and liability determination.

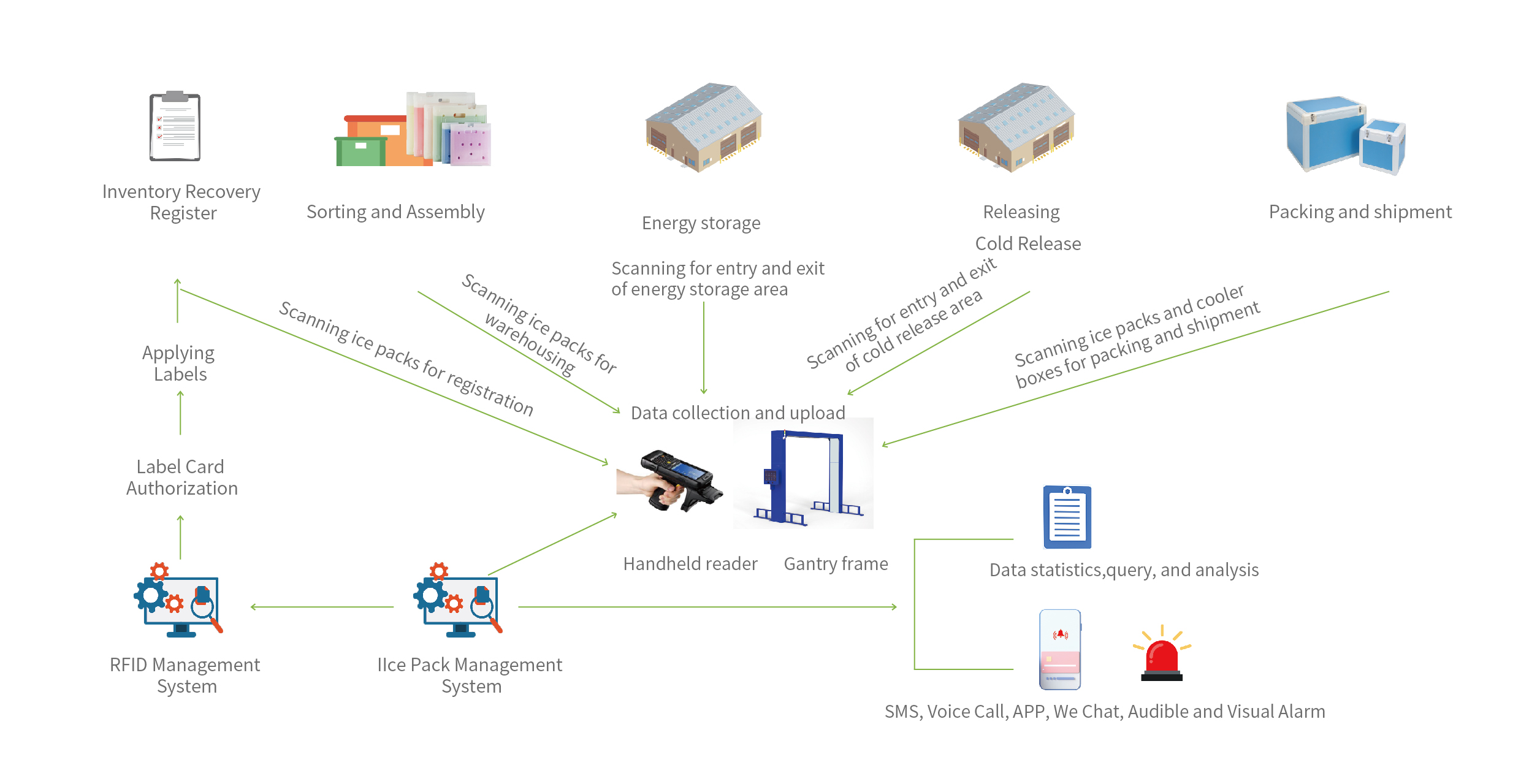

Full - Process Control and Intelligent Management

The operation process of the CCTS CHINA system is standardized. Starting from coding and labeling, it lays the foundation for the full - life - cycle management of assets. Assets are registered when they are put into storage. Then, ice packs are sorted and combined according to the packing plan and respectively subjected to energy storage and cold - release treatments. Each link is scanned and recorded to ensure the accuracy of information. When packing, the binding relationship between ice packs, drugs, and insulation boxes is scanned and confirmed again. When shipping, the insulation boxes are scanned to confirm shipment, and there is also a corresponding scanning process during recycling. The entire process forms a closed loop, achieving full - process traceability.

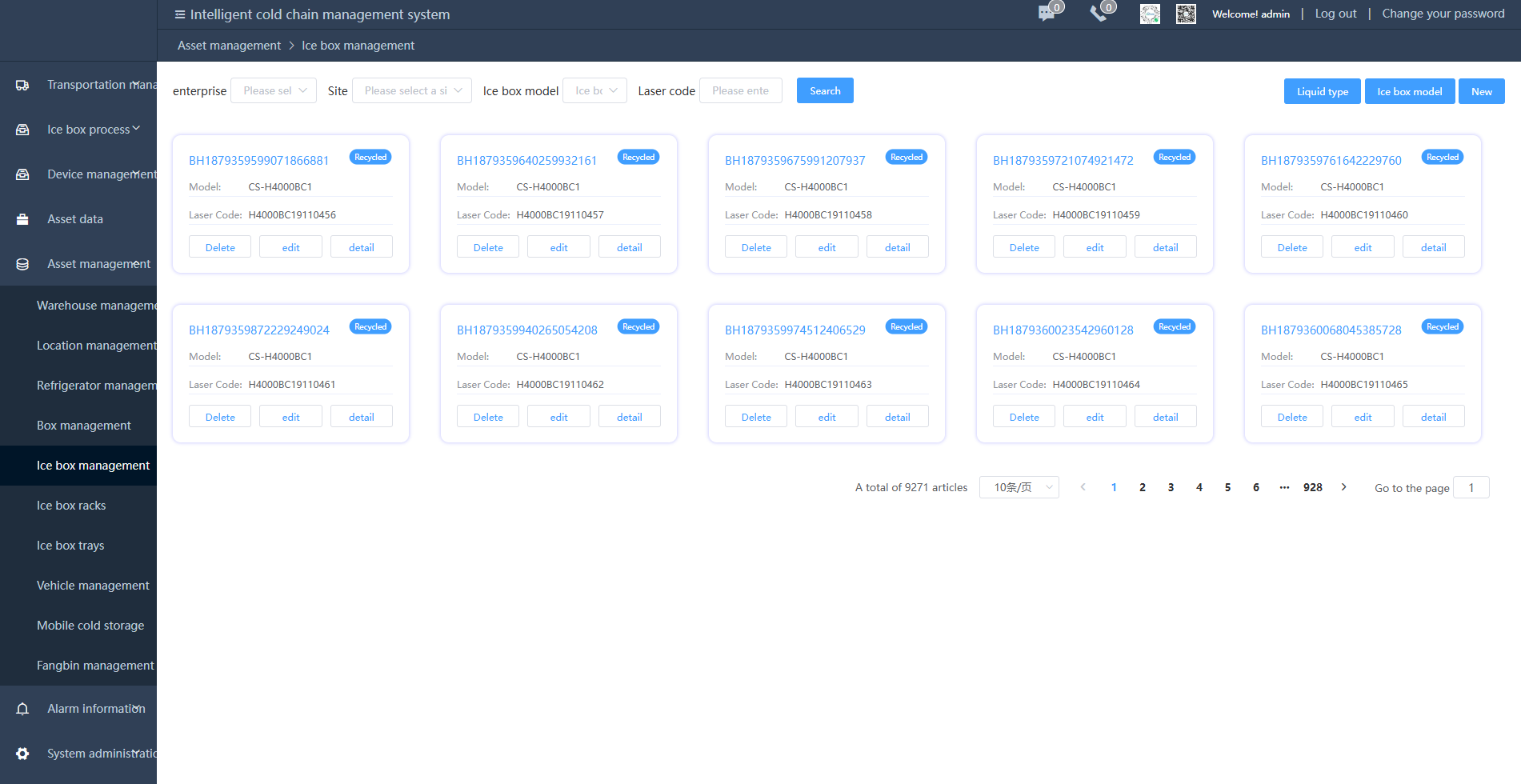

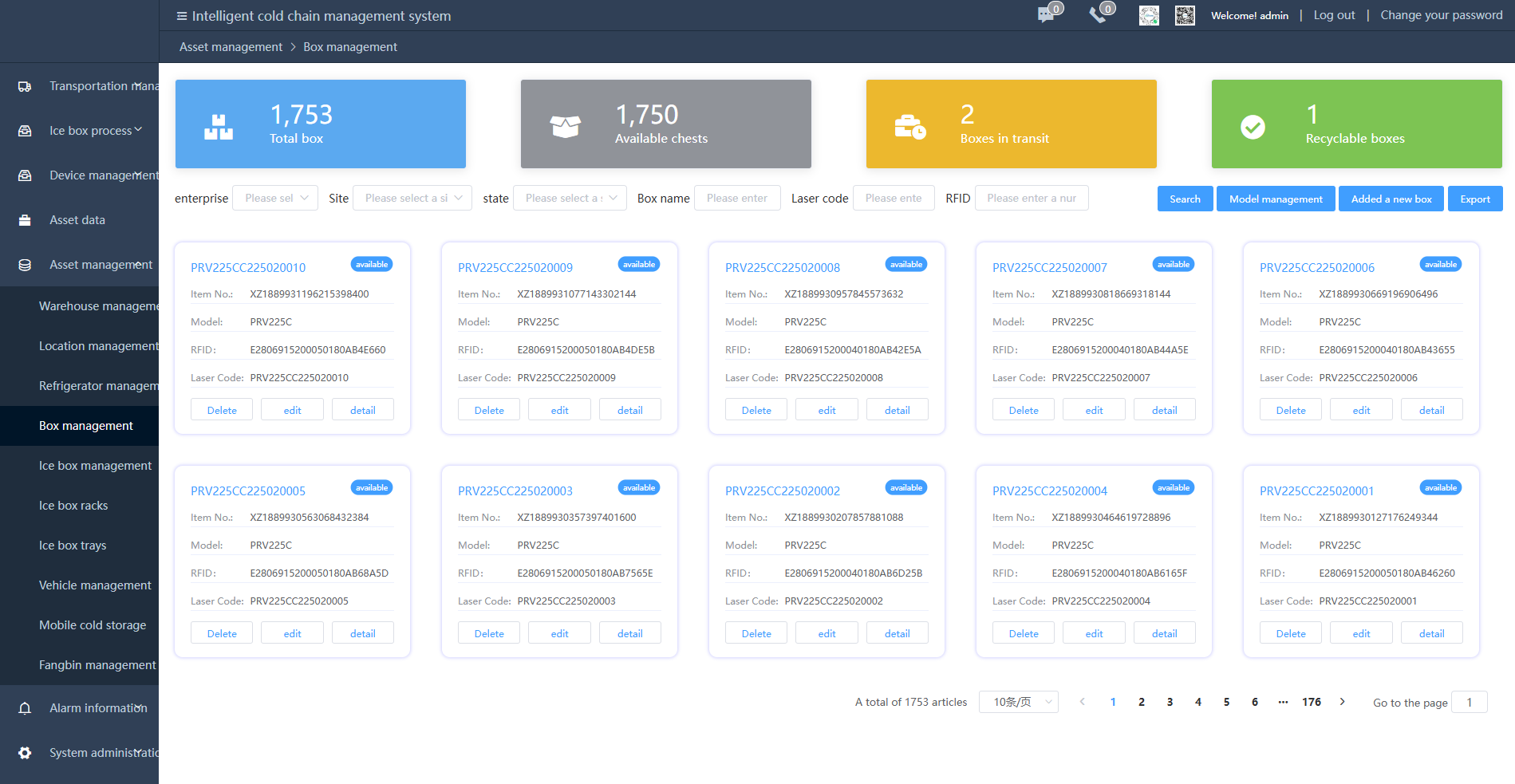

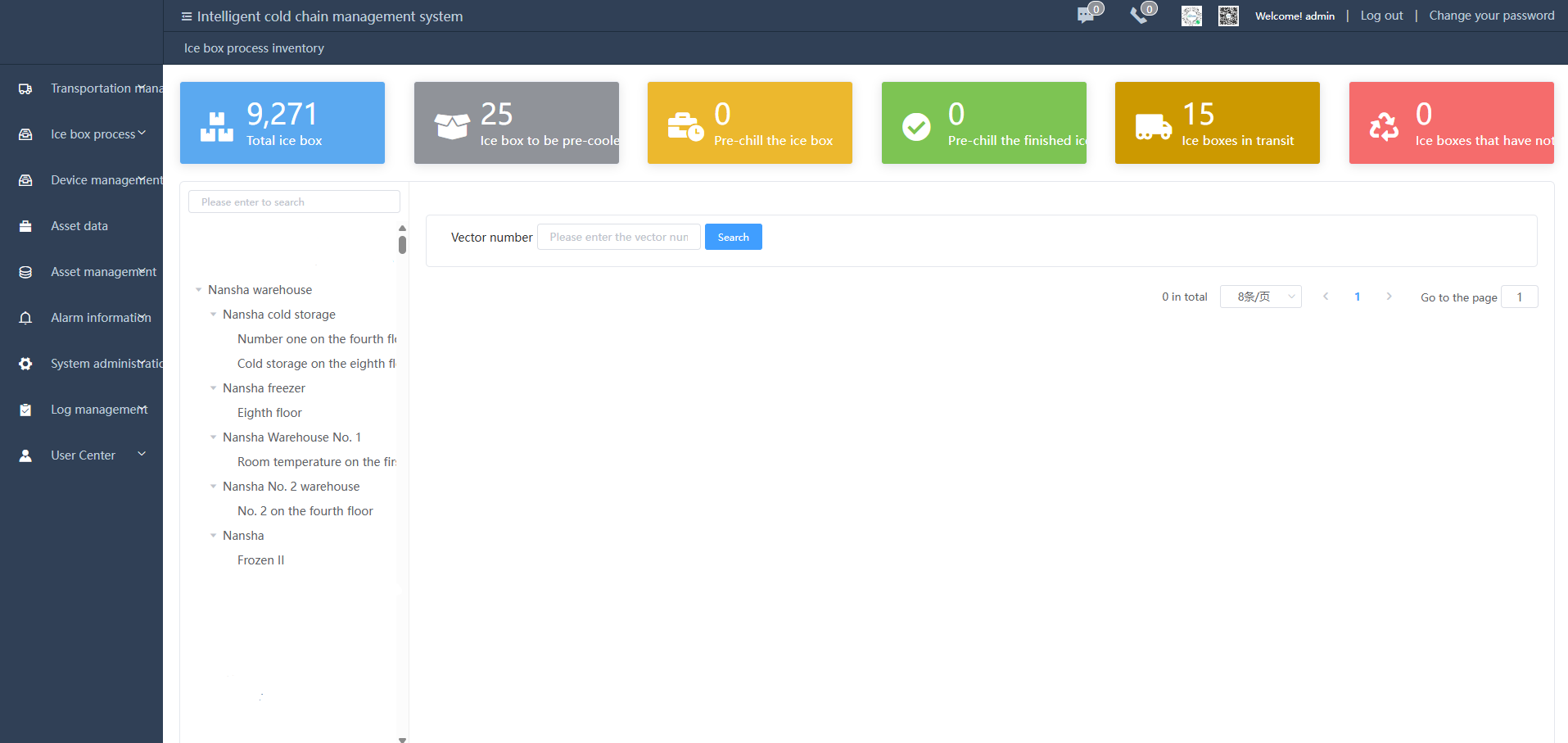

Smart management, powerful functions

Its intelligent cold chain management system has rich functions, covering multiple modules such as asset management, warehouse management, and transportation management. In terms of asset management, it uniformly manages assets such as refrigerators, boxes, ice boxes, and ice racks, and monitors the asset status in real - time. The warehouse management module can perform operations such as warehouse setting and inbound and outbound management. The transportation management module realizes functions such as viewing the transportation list, monitoring transportation, and managing waybills. It can also monitor the temperature during transportation in real - time. Once the temperature exceeds the standard, it will immediately issue an alarm through various means such as text messages, voice, APPs, WeChat, and sound and light.

Technology - Enabled and Unlimited Prospects

The success of the CCTS CHINA Cold Chain RFID Asset Management System is inseparable from strong technical support. The RFID technology it uses has advantages such as fast identification speed, high accuracy, and the ability to simultaneously identify multiple tags. The Internet of Things technology enables the interconnection and interoperability of devices, allowing for real - time data sharing. Big data algorithms analyze and process massive data, providing a basis for management decision - making.

In the future, with the further integration of technologies such as 5G and artificial intelligence, the CCTS CHINA system will become more intelligent and efficient. It is expected to play an important role in more fields such as the cold chain transportation of fresh agricultural products and the logistics of products with high environmental requirements such as electronic chips, continuously improving management levels, reducing costs, and ensuring product quality. With the continuous progress of technology, the CCTS CHINA system will also continue to be upgraded and expand more functions, such as achieving intelligent prediction and automatic control through artificial intelligence, injecting a continuous stream of impetus into the development of the cold chain industry.